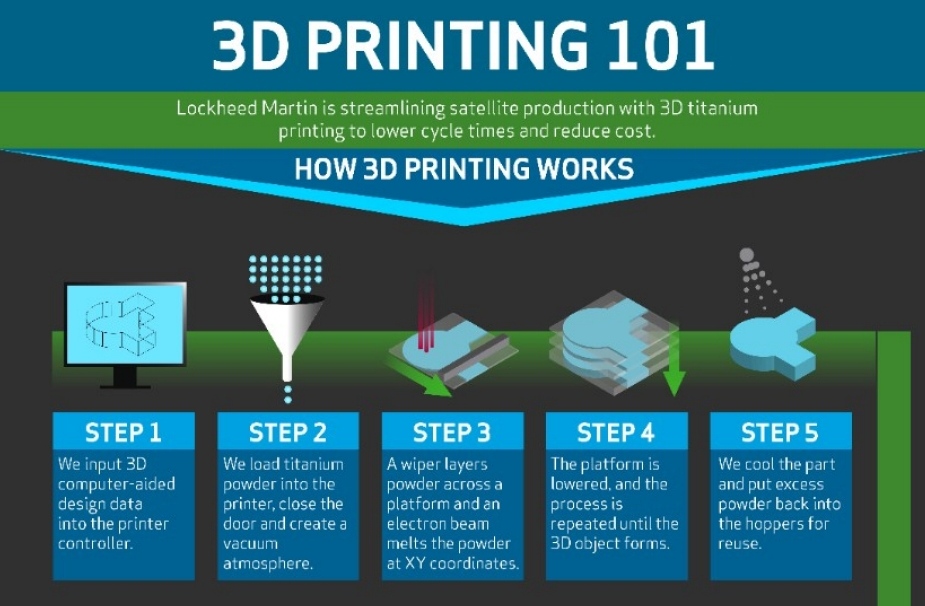

Lockheed Martin says 3D printing could completely change the space industry. Lockheed graphic.

Artificial intelligence, smaller, cheaper, and re-programmable satellites, and 3-D or additive manufacturing will combine to drive big changes in the space industry, Lockheed Martin’s chief space executive reported Monday.

Rick Ambrose, Lockheed executive vice president for space, predicted that satellites will soon be built “at half the cost and delivery time” of satellites built today, which have already seen a big cost shrinkage. Driving the reduction will be the more widespread use of additive manufacturing, which will sharply reduce the duration and cost of the prototyping phase of development and will allow unique parts to be made rapidly.

Additionally, more sensor and functionality can be packed into smaller satellites, making larger and more resilient constellations possible, he said at a Lockheed Martin “media day” outside Washington, DC. “Smallsats will pack a big punch as part of diverse constellations,” Ambrose said, and smallsats coupled with a few large satellites will be “very powerful.” They will be more flexible and rapidly put “bandwidth [and] sensors where you need it most.” Additive manufacturing will “transform the way we build” satellites, and future spacecraft will probably take along 3-D printing equipment to build their own upgrades, Ambrose said, since they are also becoming longer-lived and will outlast their initial technology.

In ground-based manufacturing, 3-D is already cutting costs and accelerating delivery times. Propellant tanks that used to take two years to make are now being printed in two months, Ambrose said. The quality of manufacturing will also rise, as 3-D printing “takes design escapes down.”

Moreover, satellites will “turn into smartphones” he asserted: hardware chassis with an ever-changing series of applications that can be updated or changed as the user’s needs change. They will be “applications talking to other applications.”

Overarching all of this will be the application of artificial intelligence, Ambrose said. AI “is the next great leap in space,” and “will turn this industry upside-down,” he insisted. It will relieve humans of mundane and repetitive tasks and free them for other functions. This will be especially noticeable for astronauts, who can devote their time to science rather than serve as babysitters and troubleshooters for hardware. The result will not be the replacement, but enhancement of humans.

“We see human more, not ‘human-less,’” he said.

AI and machine-to-machine learning will be able to solve problems “without being told how,” Ambrose said, using what he called “synthetic persistence.”

Paired with additive printing, AI will be powerful, allowing engineers to use “augmented reality” to design better spacecraft, and even assess the human workers doing production, pointing out if they are making mistakes and pointing out problems.

It will be “wearable” and “spot problems with the technician,” said Ambrose, nothing the reduction of problems in the factory will speed the time to market.

He also predicted that spacecraft will continue to be the lion’s share of the space enterprise, with launch services only representing about two percent of the market. Space companies do space launch because it’s necessary to get their products into orbit, but that may change as launch specialists continue to enter the business.

Ambrose anticipates more “public-private” partnerships, and contracts that will continue to be both fixed-price or cost-plus, depending on the desired application.