In the 1940s, the United States produced a bomber with capabilities so advanced that it required a national revolution in engineering, aerodynamics, manufacturing, electronics, material, and operation. And so did the Soviet Union.

The US spent more on its new bomber than it had on any previous aviation project. The Soviet Union did the same.

The US aircraft—the B-29 Superfortress—made history on Aug. 6, 1945, when it dropped an atomic weapon on Hiroshima. The Soviet aircraft went on display on Aug. 3, 1947 at the annual Tushino air show. Visitors in Moscow that day witnessed a stunning flyover: the debut of the Tu-4 bomber.

|

|

Here’s the odd thing. The monumental US and USSR bomber programs had produced what was, for all intents and purposes, the same aircraft.

The three Tu-4s flown at the air show were indistinguishable from US B-29s, the state-of-the-art aircraft that had revolutionized long-range strategic bombing.

Western observers initially believed—hoped—that the aircraft seen at the Moscow air show were actually three B-29s that had made emergency landings in the Soviet Union near the end of World War II. But there was also a Tu-70 passenger version of the B-29 in the flyby that day, which forced the observers to accept a troubling fact.

The Soviet Union had done the impossible: It had reverse engineered and produced flyable B-29 replicas in two short years. The Tu-4 was a virtual carbon copy of the Superfortress.

Rise into the Modern Age

The Tu-4s gave the Soviet Air Force a strategic air arm that posed a genuine threat to the Free World. By 1950, more than 270 Tu-4s were deployed in Soviet Long-Range Aviation regiments. NATO gave the bomber the code name Bull, and by the Korean War, there were enough available for the Soviets to put them in the service of the People’s Republic of China.

The Tupolev Tu-4 took part in no decisive battles, but its effect on Soviet aviation was incredibly important. The Bull brought the entire Soviet aircraft industry, from its design bureaus to its most insignificant parts supplier, into the modern airpower age.

The Soviets made remarkable progress in producing nuclear weapons, but without the amazingly rapid production of the Tu-4, the USSR could not have delivered those weapons for many years.

The US B-29 effort was an immense undertaking. Program cost estimates vary, but it is generally stated that the entire B-29 effort cost about $3 billion—more than the Manhattan Project that developed the world’s first nuclear weapons. Huge new plants were built for the three companies that manufactured airframes—Boeing, in Renton, Wash., and Wichita, Kan.; Bell in Marietta, Ga.; and Martin in Omaha, Neb.

The B-29 was at the time the heaviest bomber ever built, dwarfing the B-17, Avro Lancaster, and Heinkel He 177.

Manufacturing contributed to the B-29 program’s size. There were four main factories, three modification centers, and the largest subcontracting program in Boeing history for equipment and subassemblies.

Equally important was the B-29’s complexity, with its new structure, pressurized crew compartments, central fire-control system, and powerful new Wright R-3350 engines equipped with two superchargers and trouble-prone propellers.

To obtain the required performance, Boeing reduced drag by specifying that the B-29 be built with smooth skin joints and flush riveting.

|

A B-29, virtually indistinguishable from the Soviet copy, skims over the clouds. |

Also a cost factor was the pell-mell speed of the program—which saw the first aircraft flown before many key systems were designed, much less tested.

The B-29 entered combat on June 5, 1944 with a raid on Bangkok. In the next 13 months, it would help win the war with Japan—and simultaneously plant the seeds for the USSR’s first great postwar bomber.

The Soviet Union had led the world in the construction and operation of large bombers in the 1930s. In the 1940s, however, the USSR turned its attention to smaller aircraft to stem the tide of World War II’s German invasion.

The Russians first became aware of the B-29 program when a talkative Eddie Rickenbacker made a controversial June 1943 trip to the Soviet Union.

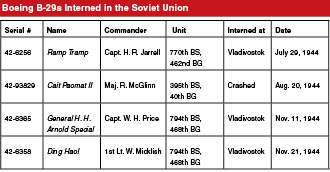

A later request for 120 Lend-Lease B-29s was ignored, but on July 29, 1944, the Soviets received a gift, seemingly out of the heavens. An intact B-29 —Ramp Tramp—was damaged in a raid on Manchuria and forced to land in Vladivostok.

Three more Superforts soon fell into Soviet hands.

Two of the bombers—General H. H. Arnold Special and Ding Hao!—landed at Vladivostok’s Tsentral’naya uglovaya, a Pacific Fleet air base; one—Cait Paomat II—crashed nearby.

The Camps

As allies, the US and USSR kept up good relations during the war, but the United States had to exert strong diplomatic pressure on the Soviets to obtain the release of almost 300 airmen who wound up in Soviet custody. The interned B-29 crews were among these guests of the Soviet Union.

As the USSR and Japan were not at war in 1944, the Soviets sought to avoid antagonizing Japan by publicly returning the Americans who had diverted after bombing Japanese targets.

The Soviets ultimately succumbed to US pressure to move the men from the harsh Siberian camps in which they were held. It was agreed first to transfer the crewmen to gulags in Central Asia where the weather was not so extreme.

|

The first Tu-4 to come off the assembly line, shown shortly after rollout in 1947. |

Treatment in the camps was primitive by American standards, but normal to the resident Russians and probably exotically luxurious to the regular gulag inmates.

There were plenty of gulags across the Soviet Union, and this network ultimately became the escape route for the American crews.

The aircrews were moved from camp to camp across Uzbekistan and Turkmenistan until the men were in a position to be smuggled across the border, into Persia—modern-day Iran—with the USSR’s cooperation.

At least four different “escapes” (called such to avoid criticism if the Japanese learned of them) took place with Soviet complicity. These escapes into British territory were orchestrated by the Soviet secret police and were done with such a degree of security that few knew the full story.

At their release, the American crew members were asked not to publicize their stories so that the escape routes would not be compromised for future prisoners.

The Soviets would not give up the B-29s the airmen flew in on, however, and began a systematic test program which ran from January to July 1945.

The three flyable aircraft were taken to the Izmailovo airfield outside of Moscow and transferred to the 65th Special Mission Air Regiment. They then came under the purview of Air Marshal Alexander Golovanov.

Stalin was distressed that the Soviet Union did not possess a strategic bomber like the B-29, and was very unhappy with aircraft designer Andrei N. Tupolev, whose own strategic bomber, Samolet 64, was not only behind schedule but also lacked essential bombing and navigation equipment.

Golovanov is reputed to have suggested to Stalin that the interned B-29s be copied and placed into production.

In June 1945, Stalin’s orders were promulgated, tasking the Tupolev design bureau to copy the B-29 and put it into production. An extremely detailed instruction placed the weight of responsibility on Tupolev’s shoulders—but also placed the whole of Russian government and industry behind him. His bureau was to break down a B-29 in the reverse order in which Boeing and its subcontractors had assembled it. All parts were to be reverse engineered, and individual elements were to be assigned to the appropriate enterprises for manufacturing. Many elements of the aircraft had never been dreamed of, much less built, in the Soviet Union, yet firms were ordered to fulfill the task.

Stalin decreed that they be copied exactly, down to the smallest detail. Any deviation in one part would inevitably lead to deviations in others, and production chaos would ensue. (Small changes were later permitted, as with the installation of Russian engines and cannon.)

This assignment seemed impossible for many reasons, not the least of which was the fact that the Soviets used the metric system.

|

Crew members of a lateproduction Soviet Tu-4 are briefed before a training mission. The Soviet Union jump-started its airpower capability reverse-engineering four US B-29s that fell into Soviet hands. (Photo from Aleksey Mikheyev collection) |

There were subtle differences between the national aerospace industries as well. The Soviet aluminum industry could not be converted to mill aluminum sheet to American dimensions. Each aluminum part had to be analyzed for its strength requirements to determine whether a slightly larger (i.e., heavier) or smaller (i.e., lighter) piece of Soviet aluminum could be used. Weight control was essential, and it is to the credit of Soviet engineers that the Tu-4 was kept within one percent of its designed weight goal.

Dimensions were not the only problem; materials also had to be reverse engineered to determine their composition, with suitable alterations then being made in what had previously been standard Russian techniques.

In some areas—plastics, electronics, navigation and radar equipment, and most particularly, the fire-control system—the complexity and sophistication of the B-29 seemed beyond Soviet attainment.

Yet Stalin decreed an ironclad two-year deadline for the program. With Stalin, the term “deadline” had a double meaning, and he used Lavrenti Beria, the notorious chief of the Commissariat for Internal Affairs (NKVD), to back up his orders with the customary Soviet brutality.

Scavenging the B-29s

No one knew this better than Tupolev, who had been arrested in 1937 on absurd charges that he had sold the Messerschmitt Me 110 design to the Germans. He began working in a gulag-like aircraft bureau in Moscow in 1939 and was not released from prisoner status until 1941 nor fully pardoned until 1955, two years after Stalin’s death.

Final control was in Tupolev’s hands. Against all odds, given the arcane interactions of the Soviet bureaucracy, what emerged was a model of managerial efficiency, one that was subsequently adapted by the Soviet Union’s successful space program.

Given Army Air Forces Chief Gen. H. H. “Hap” Arnold’s patronage of the B-29, the General H. H. Arnold Special was chosen to be disassembled and copied.

Ding Hao! was grounded for use as a back-up reference.

Ramp Tramp continued to fly for almost a decade, doing test work that included air-launching the near-supersonic rocket-powered Samolet 346 test aircraft.

Parts were scavenged from Cait Paomat II, the one Superfort that had crashed.

|

The Soviet Union scrupulously upheld agreements with Japan by interning US aircraft and crews making emergency landings in Soviet territory. Crews were treated roughly and secretly released, through Iran, in January 1945. |

General H. H. Arnold Special was carefully broken down into separate assemblies. These were further disassembled, with each of the thousands of pieces—metal, instruments, radios, wiring, motors, ducts, vents, Dzus fasteners, everything—measured, photographed, weighed, and given a detailed written description. All parts were analyzed to determine the material from which they were made. The products of modern American chemistry—plastic, synthetic fabrics, lubricants—were especially challenging.

Draftsmen working around the clock created thousands of engineering drawings, each one including the key transition from American measurement standards to the metric system.

While Tupolev, a master politician, dealt with the key government, party, and service officials, his team at the design bureau managed the “routine” of cloning a weapon system. Special teams were assigned responsibility for each and every element removed from the B-29.

Tupolev mustered his industry, calling on scores of design bureaus, dozens of research institutes, and hundreds of factories. Their task was to create duplicates of the parts being removed from the B-29 and establish the manufacturing facilities to produce them in quantity.

The Tupolev design bureau carefully monitored the quality of the products. Some suppliers lobbied for their own products or manufacturing techniques, but Tupolev demanded conformance to the Boeing sample. In addition to the risk of cascading effects from a change, Tupolev realized that Beria might perceive some change, however innocuous, as being treason.

|

Artist’s rendering of the Tupolev Tu-4 Bull No. 220504, as it appeared in the late 1950s at Bagerovo AB, Ukraine. (Artwork copyright Zaur Eylanbekov) |

It was Tupolev’s good fortune that there was a suitable substitute for the B-29’s Wright R-3350 engine available, the Shvetsov ASh-73TK. The Soviet aircraft engine industry had licensed Wright products for years, building many adaptations of them. The ASh-73TK offered 2,300 horsepower and, while ultimately reliable, suffered some of the same teething problems encountered by the R-3350—including induction system fires.

In many ways, the biggest challenge of the B-29-to-Bull process was in its electronic systems, particularly the central fire-control system (CFCS) that used General Electric analog computers to aim and fire weapons remotely. The CFCS was vital because the B-29 was pressurized, and large apertures for the guns were out of the question. It was an extremely complex system that called for a host of intricate parts and switches unknown to Soviet industry.

Rolling Off the Line

Yet the Tupolev team pulled it off, and went on to substitute 23 mm cannon for the American .50 caliber machine guns.

By late summer 1946, a full-scale mock-up of the Tu-4 was ready, and Ramp Tramp was being used to gather data and check out the flight crews who would test the Tu-4.

The first production facility at Plant No. 22 in Kazan was hurriedly outfitted with the necessary templates, machine tools, jigs, and other equipment necessary for mass manufacture. Thousands of workers had to be taught new skills, and everyone worked 12 to 14 hours a day, seven days a week. Later, additional production came from Plant 18 in Kuibyshev and Plant 23 in Moscow.

Not content with duplicating the B-29, Tupolev also began the design and construction of a passenger version, the Tu-70, which flew on Nov. 27, 1946—six months before the Bull bomber itself.

The first Tu-4 rolled out on Feb. 28, 1947, to the delight of the factory workers and to Tupelov’s profound relief. As aircraft came off the production line, they were entered into a 20-airplane test program for the state acceptance program.

|

The Bull eventually served in a variety of roles, including that of a tanker. Here, two MiG-15s approach a pair of Tu-4s, ready to take on fuel. |

First flight for the Bull bomber took place on May 19. The effort must have seemed worthwhile when the first three Tu-4s flew at the August Moscow air show, with Golovanov in one aircraft, creating an international furor.

The Soviets continued a testing role for the Tu-4s, most notably using the Bull for the first airdrop of a Soviet atomic bomb on Oct. 18, 1951.

The Tu-4 eventually served in many roles—anti-shipping, tanker, reconnaissance, missile launcher, drone carrier, and engine test bed—before retirement. But its most important contribution by far was spring-boarding the Soviet Union to a leading role in developing air and space power.

The crews of the four B-29s that made their way to Vladivostok had no idea how much of an effect their distressed aircraft would ultimately have.

Walter J. Boyne, former director of the National Air and Space Museum in Washington, D.C., is a retired Air Force colonel and author. He has written more than 600 articles about aviation topics and 40 books, the most recent of which is Hypersonic Thunder. His most recent articles for Air Force Magazine, “Ring of Remembrance” and “They Wanted Wings,” appeared in the February issue.